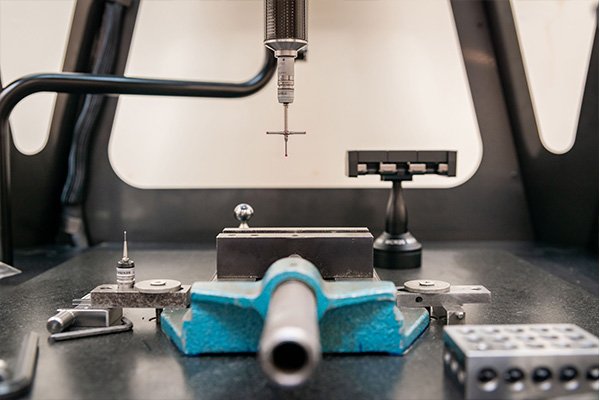

A fully equipped temperature-controlled inspection department for both in-process and final inspection.

A good stock of conventional metrology equipment is complemented with digital height gauges, hardness testing, shadowgraph and Faro arm.

Wherever possible, calibration of equipment is carried out in-house using equipment externally calibrated to national standards.

For calibrations beyond the scope of our own facility, the services of a UKAS accredited laboratory are retained.

Our equipment includes:

Doosan Puma GT2600

Single Spindle 2 axis lathe with tailstock

12 Station Turret

Max Turning Diameter 460mm

Max Turning Length 650mm

Bar Capacity 81mm

Fitted with Hydrafeed magazine Barfeed

Doosan Puma GT2600M

Single Spindle 3 axis lathe with tailstock

Full C axis with live Tooling

12 Station Turret

Max Turning Diameter 460mm

Max Turning Length 650mm

Bar Capacity 81mm

Citizen L20 Type VII

Twin spindle 7 axis sliding head CNC lathe

16 Tools – 6 turning, 4 driven, 3 front machining 3 back machining

Long parts ejector up to 600mm

3 mtr Iemca magazine barfeed

Bar Capacity 20mm

Citizen C32 Type VIII

Twin spindle 6 axis sliding head CNC lathe

18 Tools – 10 turning, 8 driven

3 mtr Iemca magazine barfeed

Bar Capacity 32mm

Citizen A32 Type VII

Twin spindle 7 axis sliding head CNC lathe

23 Tools – 6 turning, 4 driven, 4 front machining 9 back machining

3 mtr Iemca magazine barfeed

Bar Capacity 32mm

Citizen A20 Type VII

Twin spindle 7 axis sliding head CNC lathe

23 Tools – 6 turning, 4 driven, 4 front machining 9 back machining

3 mtr Iemca magazine barfeed

Bar Capacity 20mm

Colchester Tornado TM8

Chucking Lathe up to 300mm dia

12 Station turret

Full C axis & live tooling

Haas TL1 Tool room Lathe

Manual & full CNC lathe

Turning dia up to 210mm

4 Station automatic toolpost

Citizen L20 Type VIII

Twin spindle 7 axis sliding head CNC lathe

Upto 26 Tools – 6 turning, 10 driven, 4 front machining 4 back machining

3 mtr Iemca magazine barfeed

Bar Capacity 20mm

LFV Technology to control swarf