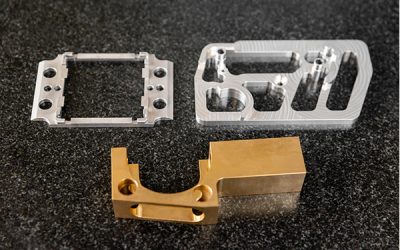

Our factory is equipped with the latest in CNC machinery including 6 axis CNC Turning, 4 axis CNC Milling operated by highly skilled, fully trained staff.

CNC Turning

We deliver high-precision turned parts, specialising in the production of 3D complex components....

CNC Milling

Our machining centres are all Haas or Doosan machines and are all equipped with a 4th Axis. Each...

Inspection

A fully equipped temperature-controlled inspection department for both in-process and final...

Prototyping

Our highly skilled team can offer assistance on design development and best machining practices....

Plating and Painting

Through our suppliers we can offer a variety of plating finishes including zinc, nickel, chrome,...

Assembly

To complement our machining facilities, we also offer an assembly service. Manufactured components...

Download the R&L Enterprises Capacity List here >>

Using the latest CAD-CAM and CNC Machining technology our highly skilled engineers can deliver precision-engineered components in a wide range of materials and sizes to suit your requirements.

Our highly skilled team can offer assistance on design development and best machining practices. We may even be able to advise on design modifications or production techniques which may reduce production costs without compromising your original specifications.

We specialise in batch sizes from 10-10000 off. We can produce parts ranging from 2-50mm diameter on bar fed CNC lathes, billets up to 250mm diameter. Most materials can be machined including plastics.

We continually invest in the latest range of CNC machinery, we are able to remain competitive and flexible in meeting our customers ever changing requirements.