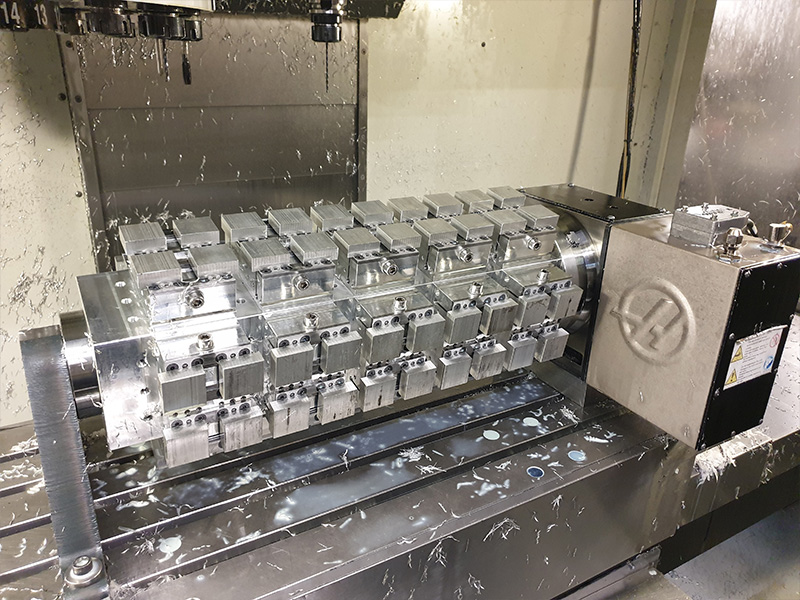

Having landed some very large batch runs on our machining centres over the past year, we felt we needed to utilise our 4th axis more and invest in trunnions so we could machine multiple parts on a 4th axis.

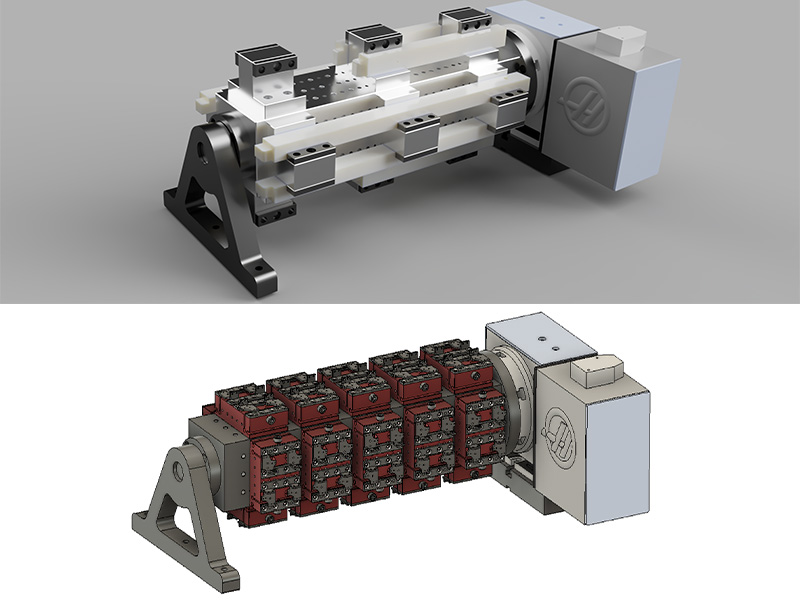

Having researched the market we could not find anything suitable off the shelf, so we made the decision to manufacture our own trunnions and fixtures.

All were designed using our Fusion 360 CAD/CAM software.

This has increased parts per load from 10 parts per load using 5 double vices to in some cases 80 parts per load on a 4 sided trunnion with parts now coming off complete.