Precision engineers R&L Enterprises continue to supply a range of industries around the world with its high quality laboratory metalware and precision engineered components.

Established in 1942 as an engineering company, R&L Enterprises has been manufacturing and supplying laboratory metalware to educational and industrial markets around the world. Its REXALOY range of products is recognised globally for its high quality, manufactured to the strictest international standards, while sticking to its UK roots. The REXALOY branded laboratory metalware range proudly displays the Made in Britain Marque, from clamps to bossheads and burners.

“All of our laboratory range that we supply is currently made in the UK, so it is an important logo to have. I think it reinforces what we already do, which is manufacturing in the UK. However, it is not just about that. Being featured on the Made in Britain website helps bring in new customers that are looking for a high-quality product. When they choose one of our products they are certain that we manufactured it here and we are not subcontracting it out anywhere else,” says Jonathan Bell, Technical Director.

As an internationally-recognised registered trademark, Made in Britain promotes and acknowledges the very best of British manufacturing. It brings together the British manufacturing community, united by the same Marque that proves manufacturers’ commitment to produce their products in the UK. Moreover, it raises awareness worldwide of the country’s manufacturing sector in a way that customers are certain they are receiving the highest quality products and services.

Over the years, R&L Enterprises has evolved tremendously and, in the 90s, it started investing in machinery. The investments had opened doors to a whole different market, pushing the company into the direction of subcontracting. Since achieving ISO9002 quality assurance accreditation back in 1992, it has remained committed to providing subcontract engineering solutions to its customers in a fast, flexible and reliable manner. Having invested heavily in a wide range of versatile CNC machinery, the company is able to meet its customers’ ever-changing requirements and supply precision engineering services to industries, such as fire suppression, pharmaceutical, rail, and telecoms.

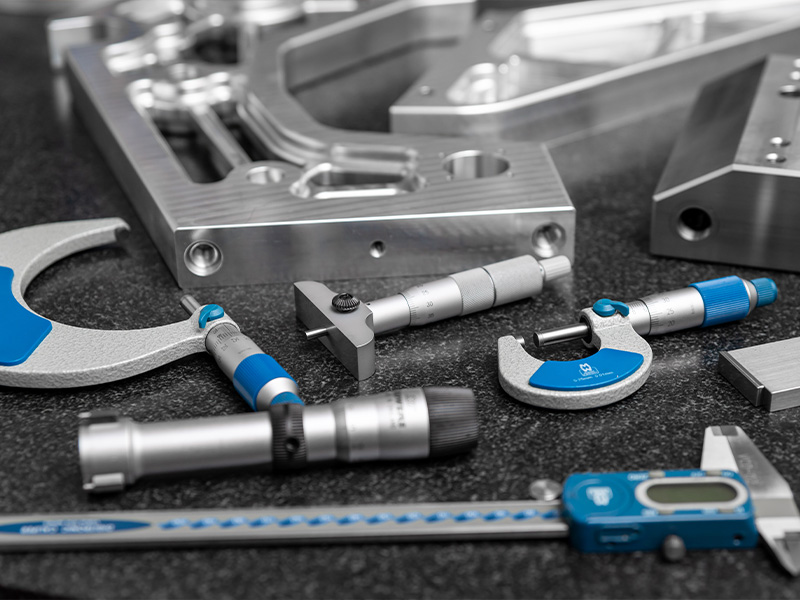

“We work with a variety of customers through all stages, from concept design to prototyping. We can also offer design ideas and practices in machine components for those customers that need unique solutions,” explains Jonathan. Indeed, from its purpose-built manufacturing plant in Leeds, West Yorkshire, R & L Enterprises can offer all CNC machining, milling, cropping, fabrication and painting, specialising in complex, high precision components. Its team of highly skilled engineers can deliver precision-engineered components in a wide range of materials and sizes to suit any requirements.

Key investments have been made in the company’s quality department, in order to ensure customers are satisfied. The most recent addition is a state-of-the-art Faro Gage Plus Arm, which offers one of the most advanced measuring systems available. It allows the easy generation of First Article Inspection Reports, whilst simple and complex measurements can be quickly undertaken compared to conventional CMM measuring. A fully equipped temperature controlled inspection department is also available for both in process and final inspection. Meanwhile, a good stock of conventional metrology equipment is complemented with digital height gauges, hardness testing, shadowgraph and faro arm.

Besides investing in the smooth running of the business, R&L Enterprises also recognises the importance of investing in people. Providing staff with the necessary knowledge to handle tools, plant and equipment in a safe manner is paramount. “While we offer our own in-house training, we also give our employees the chance to go on CAD CAM courses. In this rapid-changing industry, our engineers need to stay on top of the latest innovative technologies. We also try to share our knowledge with apprentices and give them hands-on experience straight onto CNC machines,” says Jonathan.

When asked what the secret to the company’s longevity and long-term relationships with its clients is, Jonathan believes communication is key. “Although at the moment the market is in a difficult position, because of the supply chain issues with materials, we thrive to be honest with our customers at all times. We are always in contact with them if we face any problems and we do our best to match their quote, while also giving them realistic times. I think this type of open communication between both parties is what has kept customers satisfied over all these years,” he explains.

From its inception up until this moment in time, R&L Enterprises has evolved into one of the UK’s most respected manufacturers of CNC precision-engineered components, supplying a wide range of industries across the world. In terms of future growth plans, the company aims to become even stronger. “Our main goal for the future is to continue to invest in new machinery and personnel to be able to deliver the highest standards in all areas of business. By doing that, we will be able to win big contracts for our customers and to keep on top of everything,” Jonathan concludes.